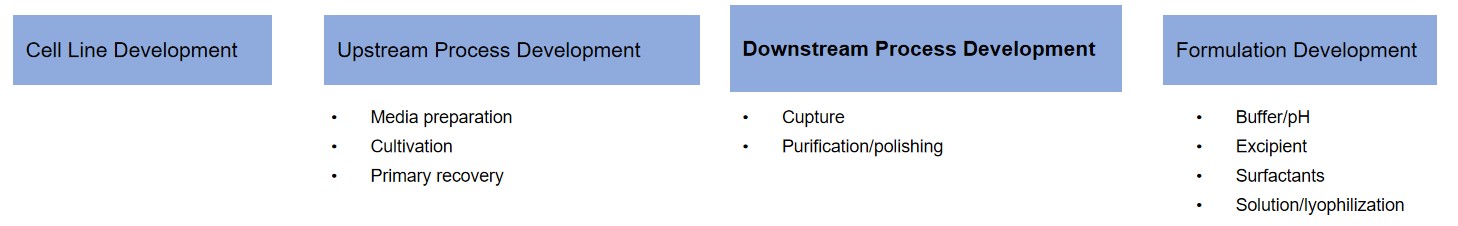

Antibody Production Downstream Process Development Service

At Creative Biolabs, we offer comprehensive downstream process development services for antibody CDMO production. In the specialized realm of antibody production, downstream process development is crucial for optimizing efficiency, scalability, and ensuring the high quality of the final product.

What is Downstream Process Development?

Downstream process development in antibody production is pivotal within biopharmaceutical manufacturing. This phase focuses on extracting and purifying antibodies from cell culture harvests using selective separation and extraction methods such as filtration, centrifugation, and chromatography. These techniques ensure the final product meets the required standards for quality, purity, and efficacy. Additionally, downstream processing involves rigorous testing for impurities and contaminants, highlighting its vital role in guaranteeing the safety, effectiveness, and excellence of the final therapeutic product.

Our Downstream Process Development Services

At Creative Biolabs, our downstream process development services are tailored to meet the diverse needs of antibody production. Our comprehensive services cover the full range of downstream processing (DSP) activities, starting from the initial recovery phase and culminating in final formulation. We offer expertise in developing purification strategies, optimizing process parameters, conducting scalability assessments, and profiling impurities. By integrating upstream and downstream processes seamlessly, we ensure a streamlined path from cell development through to final product purification and formulation.

- Resin screening

- Chromatography process development

- Viral clearance studies

- Ultrafiltration (UF)/Diafiltration (DF)

- Process characterization

- Process scale-up

Typical Key Steps of Downstream Process

- Harvest and Filtration: Utilizing advanced techniques such as depth filtration and hollow fiber systems to efficiently separate cellular debris and collect the target product.

- Primary Capture: Employing affinity and ion exchange methods to selectively isolate and concentrate the desired molecule from the mixture.

- Viral Inactivation: Implementing low pH treatment to ensure the safety and purity of the product by effectively neutralizing potential viral contaminants.

- Buffer Exchange and Concentration: Employing advanced ultrafiltration and diafiltration techniques to facilitate the exchange of buffers and concentrate the product, enhancing purity and stability.

- Polishing: Further purification or polishing may be conducted to ensure the removal of trace levels of impurities that could affect product quality. This often involves one or more additional chromatography steps.

- Formulation: Tailoring the final product into its intended formulation, ensuring stability and activity are maintained for its specific application.

Contact Us

Downstream process development is a crucial step in antibody CDMO production, and at Creative Biolabs, we offer unparalleled services to ensure the success of your biopharmaceutical endeavors. By focusing on tailoring processes to meet specific product characteristics and regulatory requirements, we are committed to delivering excellence in every project. For more detailed information about our services or to discuss your specific project needs, please contact us.

For research use only. Not intended for any clinical use.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.