AI-based High Throughput Antibody Fc Engineering Service

At our high throughput antibody production service, Creative Biolabs leverages artificial intelligence (AI) to enhance antibody Fc engineering for improved therapeutic outcomes. Our state-of-the-art platform enables rapid screening and selection of antibodies with optimized Fc regions for enhanced functionality, such as improved antibody-dependent cellular cytotoxicity (ADCC) and complement-dependent cytotoxicity (CDC) activity.

Antibody Fc Engineering

Antibody Fc engineering refers to the process of modifying the Fc region of an antibody molecule to enhance its biological functions or properties. This can involve changes to the Fc region's structure, glycosylation pattern, or affinity for Fc receptors on immune cells, among other modifications. The goal of antibody Fc engineering is to generate antibodies with improved therapeutic efficacy, such as increased potency, longer half-life, or enhanced effector functions.

Featured Antibody Fc Engineering Platform Based AI at Creative Biolabs

Our team of experts will work closely with you to design and execute customized antibody engineering strategies, using our scalable production platform to generate large quantities of high-quality antibodies for further evaluation. With our high-throughput approach, we can quickly identify lead candidates with superior Fc properties, saving you time and resources in the drug development process.

Antibody Fc Engineering Strategies

Antibody Fc engineering is a field within biotechnology that focuses on manipulating the fragment crystallizable (Fc) region of antibodies to enhance their therapeutic properties and functions. Creative Biolabs provides antibody Fc engineering services that can assist in the design, optimization, and characterization of engineered antibodies for various applications in biotechnology and medicine.

Fc glycoengineering

This involves modifying the glycan structure attached to the Fc region of antibodies to enhance their effector functions, such as antibody-dependent cellular cytotoxicity (ADCC) and complement-dependent cytotoxicity (CDC).

Fc receptor engineering

By modifying the Fc region to increase its affinity for certain Fc receptors on immune cells, the antibody can more effectively engage with these receptors and elicit an immune response.

Fc fusion proteins

Antibodies can be engineered to have a fusion protein attached to their Fc region, which can extend their half-life in circulation or target specific cell types or tissues.

Fc domain swapping

By exchanging the Fc region of one antibody with the Fc region of another antibody, novel antibodies with unique characteristics and functions are created.

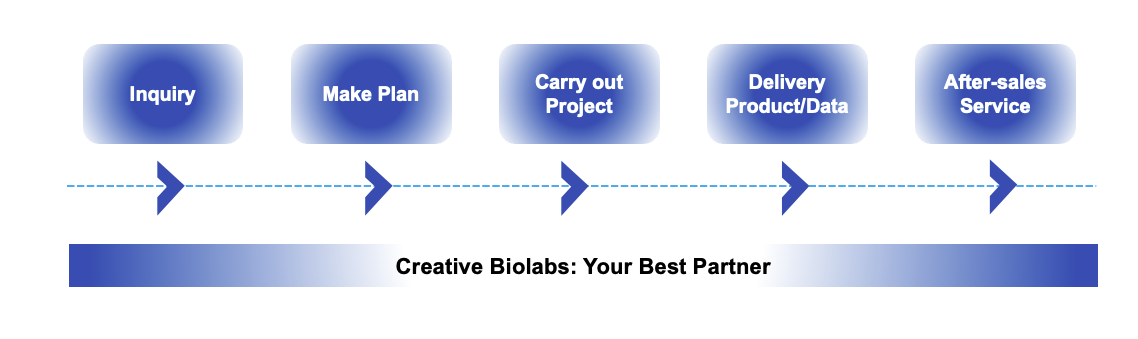

Process of Our Service

The high throughput antibody production service for AI-based Fc engineering involves a systematic process of antibody selection, variant generation, screening, characterization, production, quality control, and final delivery. We use artificial intelligence to optimize antibody production processes, increasing efficiency and throughput for engineering Fc domains.

Generation of initial antibody variants

Once the target antibody is selected, a library of antibody variants is generated using various techniques such as phage display or yeast display.

Characterization of selected candidates

The selected Fc-engineered antibody candidates are further characterized to assess their stability, specificity, and functionality.

Quality control and validation

The Fc-engineered antibodies undergo rigorous quality control testing to ensure their safety and efficacy.

Selection of antibody target

The first step is the selection of the target antibody to be engineered.

Screening for Fc engineering candidates

The generated antibody variants are then screened for desired Fc engineering characteristics such as improved binding affinity, enhanced effector functions, or reduced immunogenicity. High throughput screening assays are used to quickly identify promising candidates.

Scale-up production

This step involves large-scale cell culture, purification, and formulation of the antibodies.

Delivery of engineered antibodies

Delivery of the Fc-engineered antibodies to the customer for their intended use.

Advantages of Our Service

Customized Antibody Production

High throughput antibody production services can provide a large number of fully customized antibodies for AI-based Fc engineering projects.

Speed and Efficiency

High throughput antibody production services can rapidly produce large quantities of antibodies, reducing the time needed for screening and selection of optimal candidates for further engineering.

Increased Success Rate

The ability to produce a large number of antibodies simultaneously increases the likelihood of finding high-affinity antibodies with the desired Fc engineering properties, leading to a higher success rate in antibody development projects.

Expertise and Support

Creative Biolabs has experienced scientists who provide guidance and support throughout the antibody production process, from design to characterization.

Scalability

High throughput antibody production services can easily scale up production to meet the demand for large quantities of antibodies, making it suitable for projects that require a high volume of antibodies for screening and optimization.

Cooperation With Creative Biolabs

Contact Us

Whether you are looking to enhance the efficacy of an existing antibody or develop novel therapeutics with improved Fc functionality, our high throughput antibody production service can help you achieve your goals efficiently and effectively. Contact us now to learn more about how we can support your antibody engineering needs.

For research use only. Not intended for any clinical use.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.