Secretory IgA (SIgA) Production Optimization Service

Introduction: The Critical Role of Secretory IgA in Mucosal Immunity

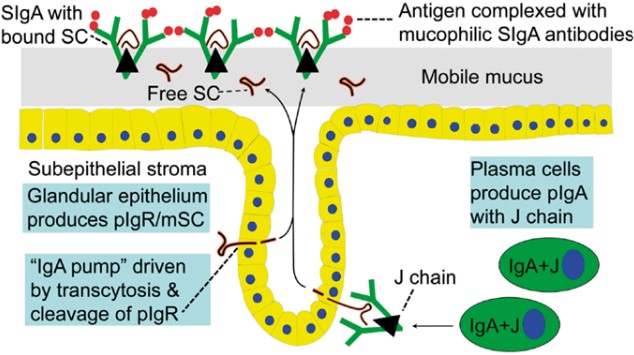

Secretory Immunoglobulin A (SIgA) stands as the primary antibody isotype safeguarding mucosal surfaces, acting as the first line of defense against a myriad of pathogens, including viruses, bacteria, and toxins. Its unique multimeric structure, comprising two IgA monomer units, a J chain, and a secretory component (SC), confers exceptional stability and non-inflammatory properties, making it uniquely adapted to the harsh mucosal environment. This inherent design, coupled with its ability to neutralize pathogens and prevent their adherence to epithelial cells, positions SIgA as an invaluable therapeutic candidate for passive immunotherapy and prophylaxis against infectious diseases.

Despite its immense therapeutic promise, the large-scale production of functional SIgA has historically presented significant challenges. Traditional mammalian cell systems often yield limited quantities, leading to prohibitive costs for widespread application. Furthermore, ensuring the correct assembly, stability, and optimal glycosylation of recombinant SIgA remains a complex endeavor. At Creative Biolabs, with over two decades of experience in advanced biologics, we recognize these critical bottlenecks and have dedicated our expertise to developing and refining cutting-edge solutions for SIgA production optimization.

Fig.1 Schematic of receptor-mediated epithelial export of pIgA to provide SIgA.1

Fig.1 Schematic of receptor-mediated epithelial export of pIgA to provide SIgA.1

Our Secretory IgA (SIgA) Production Optimization Service

Creative Biolabs' Secretory IgA Production Optimization Service is engineered to overcome the inherent complexities of SIgA manufacturing, delivering high-yield, functionally robust, and stable recombinant SIgA for diverse therapeutic and prophylactic applications. Our service integrates advanced molecular biology, sophisticated expression platforms, and rigorous biochemical characterization to ensure the highest quality product. We leverage our deep understanding of SIgA's intricate structure and assembly pathways to design bespoke production strategies that maximize efficiency and efficacy.

Our commitment at Creative Biolabs is to accelerate the development of SIgA-based therapeutics by providing a streamlined, cost-effective, and scalable production pipeline. From initial construct design to final purification and characterization, our comprehensive service ensures that our clients receive SIgA complexes optimized for their specific downstream applications, whether it be for mucosal vaccines, topical microbicides, or other innovative immunotherapies.

Service Content

Creative Biolabs' service encompasses a multi-faceted approach to SIgA production, drawing upon the latest advancements in recombinant protein expression and engineering. Our methodologies are meticulously designed to address the unique challenges associated with SIgA, ensuring superior assembly, stability, and functional integrity.

Advanced Recombinant Expression Platforms

Creative Biolabs offers unparalleled expertise in utilizing and optimizing diverse expression systems for SIgA production:

- Plant-Based Expression Systems: We specialize in leveraging the cost-effectiveness and scalability of plant-based platforms. These platforms have the capacity to produce IgA antibodies with high yields and superior assembly rates. What is more, these platforms are particularly advantageous for large-scale therapeutic production, offering a safe and readily scalable alternative to traditional mammalian systems.

- Mammalian Cell Engineering: For projects requiring specific mammalian post-translational modifications or where mammalian cell culture is preferred, Creative Biolabs employs advanced mammalian cell lines, including Chinese Hamster Ovary (CHO) cells. We draw upon breakthroughs in engineering single mammalian cells to produce and secrete covalently joined SIgA, a significant advancement that allows for efficient production of large quantities of SIgA with defined specificity, previously only achievable through complex coculture systems. Our strategies focus on optimizing expression vectors and utilizing BAC-based systems to achieve high yields and efficient assembly.

Molecular Engineering for Enhanced Stability and Assembly

Optimizing the intrinsic properties of SIgA is paramount for its therapeutic efficacy. Creative Biolabs employs sophisticated molecular engineering techniques to achieve this:

- Targeted Mutagenesis for Stability: We implement targeted single mutations to facilitate alternate disulfide bond formation between heavy and light chains, significantly improving the thermal stability of SIgA. This approach has been critical in enhancing SIgA's resistance to degradation under physiological and acidic conditions, making it suitable for applications like aerosolization and topical delivery.

- Optimization of Assembly Pathways: Recognizing that J chain incorporation can be a limiting factor, Creative Biolabs investigates and optimizes factors contributing to IgA dimerization. This includes the strategic use of Endoplasmic Reticulum (ER) retention signals on heavy chains and secretory components to enhance antibody production and stability within the ER. Furthermore, we explore the overexpression of ER chaperones to boost SIgA yields by facilitating proper folding and assembly.

Precision Glycoengineering

Glycosylation plays a crucial role in SIgA's stability, interaction with mucosal components, and overall function. Creative Biolabs' expertise in glycoengineering ensures optimal glycosylation profiles:

- Tailored Glycan Structures: We leverage glycoengineered plant platforms to produce SIgA with specific N-glycan structures. These platforms are engineered to lack plant-specific modifications, which are often undesirable for human therapeutic applications. Our analyses reveal predominantly high mannose structures, with careful control over complex glycosylation.

- Functional Implications of Glycosylation: While plant-produced SIgA may have different glycan profiles from human colostrum-derived SIgA, our studies confirm that these antibodies retain crucial functional interactions. We continuously investigate the functional significance of plant-specific O-glycosylation (e.g., hydroxyproline conversion in the hinge region) to ensure product integrity and efficacy.

Robust Purification

Efficient recovery and effective delivery are integral to SIgA's therapeutic application. Creative Biolabs develops and implements optimized downstream process.

- Streamlined Purification: We employ robust purification strategies, such as Protein L affinity chromatography, which is particularly effective for SIgAs containing specific binding determinants and overcomes limitations of traditional Protein A/G matrices, especially given the absence of certain O-glycans in plant-produced SIgAs.

Our Advantages

At Creative Biolabs, our two decades of experience in the biologics industry, coupled with our deep scientific understanding and cutting-edge technological capabilities, provide a distinct advantage in the field of SIgA production optimization.

- Integrated Scientific Expertise

- Proven Track Record of Success

- Scalability and Cost-Effectiveness

- Comprehensive Functional Characterization

- Tailored Solutions for Specific Applications

FAQs

Q1: What types of Secretory IgA (SIgA) can Creative Biolabs produce?

A1: Creative Biolabs is equipped to produce various SIgA formats, including human IgA1 and IgA2, as well as engineered variants designed for enhanced stability or specific functional properties. We can also accommodate different antigen specificities based on client needs.

Q2: What are the primary advantages of using Creative Biolabs' plant-based production platform for SIgA?

A2: Our plant-based platforms offer significant advantages in terms of scalability, cost-effectiveness, and speed of production. They are particularly well-suited for large-scale manufacturing of biologics, providing a safe and efficient alternative to traditional mammalian cell culture systems.

Q3: How does Creative Biolabs ensure the stability of the produced SIgA?

A3: Creative Biolabs employs a multi-pronged approach to enhance SIgA stability. This includes molecular engineering strategies such as targeted mutations to improve intrinsic stability, optimization of ER retention and chaperone expression for proper folding, and precise glycoengineering to ensure appropriate glycosylation patterns that contribute to protease resistance and mucosal persistence.

Q4: Can Creative Biolabs assist with the formulation and delivery aspects of SIgA therapeutics?

A4: Yes, Creative Biolabs provides expertise in developing suitable formulations for SIgA delivery. Our research has demonstrated the feasibility of aerosolization for respiratory delivery, and we can explore other topical delivery methods to ensure the SIgA reaches its target mucosal site effectively.

Contact Us

To learn more about Creative Biolabs' Secretory IgA Production Optimization Service and how we can support your therapeutic development efforts, please contact our expert team. We are committed to partnering with you to bring innovative SIgA-based immunotherapies to fruition.

Reference

- Brandtzaeg, Per. "Secretory IgA: Designed for Anti-Microbial Defense." Frontiers in immunology vol. 4 222. 6 Aug. 2013. DOI: 10.3389/fimmu.2013.00222. Distributed under Open Access License CC BY 4.0, without modification.

For research use only. Not intended for any clinical use.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.